01 — activities and products

ACTIVITIES

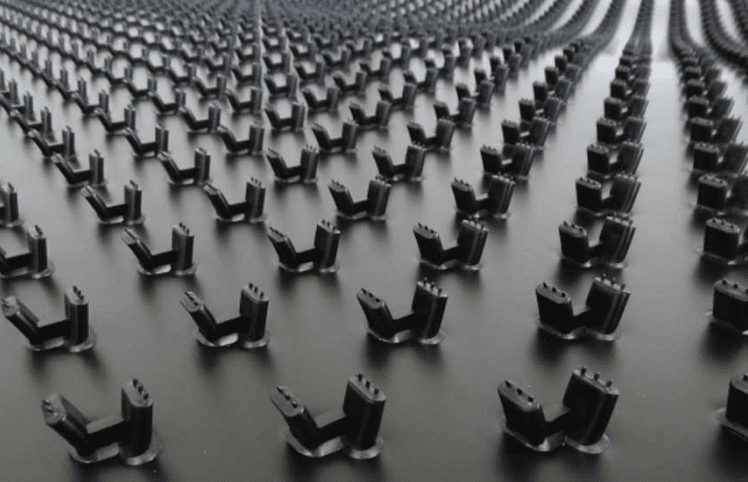

Manufacturing tie plates used to protect concrete and reinforced concrete against the impact of the external environment. Our Company uses high strength polyethylene HDPE as a source material.

Composite materials are taking the lead in many industries. The use of advanced lightweight materials based on glass fibre allows the large-scale manufacture of complex products of precise geometry. One of the most advanced and actively developing methods for composite processing is SMC technology.

The Plant operation is aimed at manufacturing plastic sheets used by industrial enterprises and construction companies. The Plant has a complete set of process equipment, including state-of-art high-performance extrusion lines.

Technical consulting services concerning the development and preparation of the manufacturing process and ensuring production process norms and product sales. 3D scanning, 3D modelling, visualisation, 3D prototyping, 3D milling, manufacturing mould pattern tooling and moulds.

This is the most common and advanced method of plastic processing that allows irregular shaped products to be produced. Currently, AO “SAPT” manufactures a variety of products by plastic injection moulding: car interior and exterior parts, medical products, lighting components, advertising products, consumer goods among others.

The technology core is feeding molten metal into a mould at high pressure, followed by rapid cooling and crystallisation. Currently, AO “SAPT” manufactures over 80 types of products. These are mainly parts for the motor vehicle industry.

Polypropylene pipes are used for heating, piping, and process plants. Polypropylene pipes are characterized by their strength, resistance to corrosion and resistance to aggressive fluids. The quality of the pipes is confirmed by Product Conformity Certificate No. ROCC RU.HB61. HO7260 dated May 26, 2020.

Our Company manufactures plastic containers of various capacity, shape, thickness and colour by rotomoulding. This method means we can make product that is both competitive in terms of price and quality and easy to operate, user-friendly and durable. Our Company is able to release various types of containers.

Manufacturing products by thermal vacuum moulding when the main process is the vacuum moulding of products with their subsequent machining. To date, AO “SAPT” processes up to 100 tons of sheets per month using this method.

Our Company has launched a new section for extrusion polymer welding to manufacture regular and irregular customised containers of polyethylene and polypropylene. The main specialisation of our production is manufacturing digestion tanks from our own polypropylene sheets.