Today AO “SAPT” is an industrial enterprise that carries out its production and business activities in the Russian motor-vehicle industry.

Launch of the foundry

Launch of the foundry. The Company released its first batch of products worth 3,000,000 RUB. The foundry products are delivered to the Pavlov Bus Plant. The total output of the Company increased to 6,000,000 RUB per month

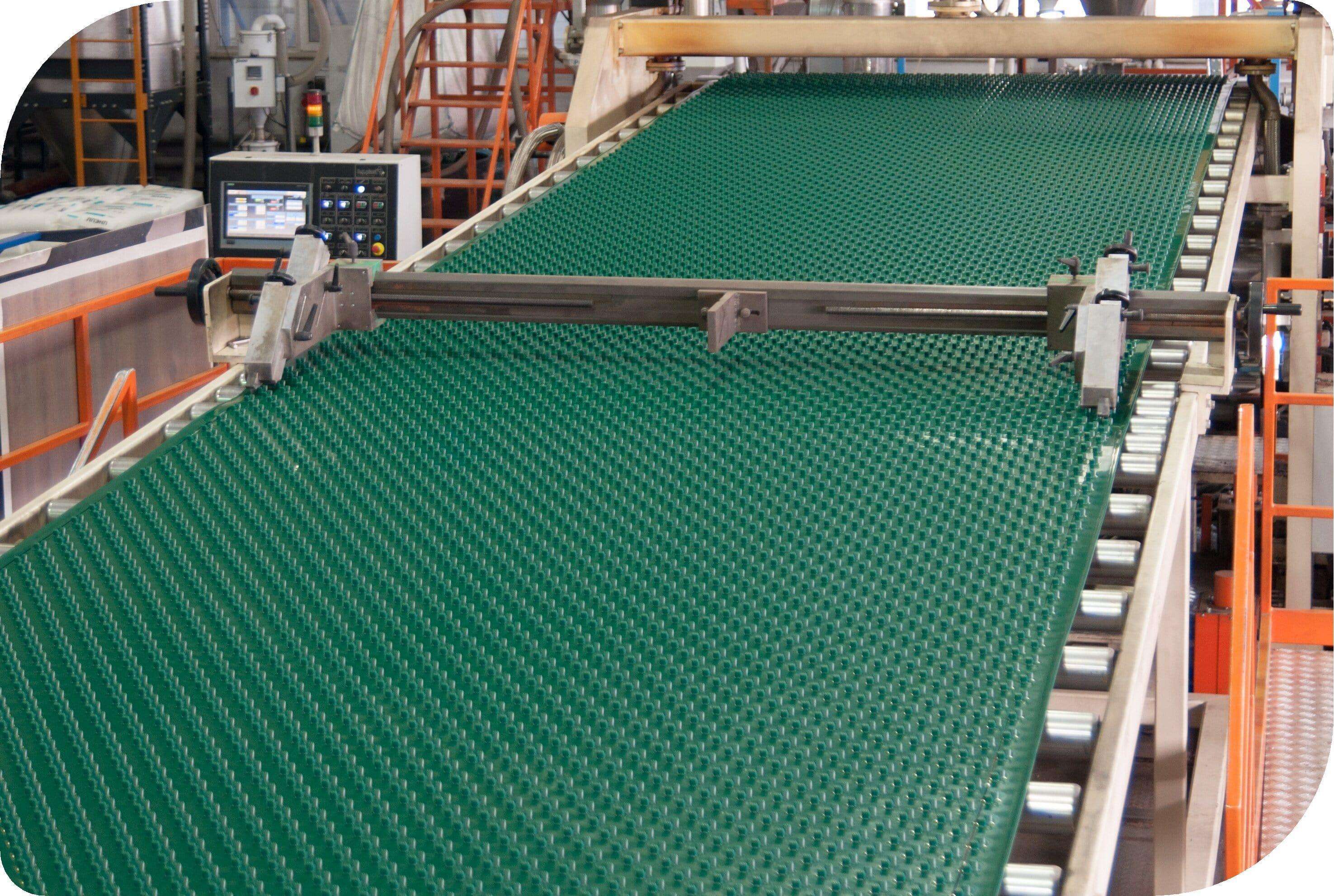

Installation and commissioning of extrusion line No. 1 and the first deliveries of ABS plastic sheets to the Pavlov Bus Factory

Construction of a new building for injection molding machines and purchase of extrusion line No. 2

The Governor of the Nizhny Novgorod region personally handed out an award for the production of quality products

Acquisition and purchase of the territory of “Agricultural Chemistry” and the start of finishing and furnishing of the Company’s road transport shop. Commissioning of wastewater treatment facilities.

Start of construction of a new building for the Injection Molding Machine Workshop

The start of finishing and furnishing of the Technical Laboratory, reconstruction and commissioning of mechanical workshop No. 2.

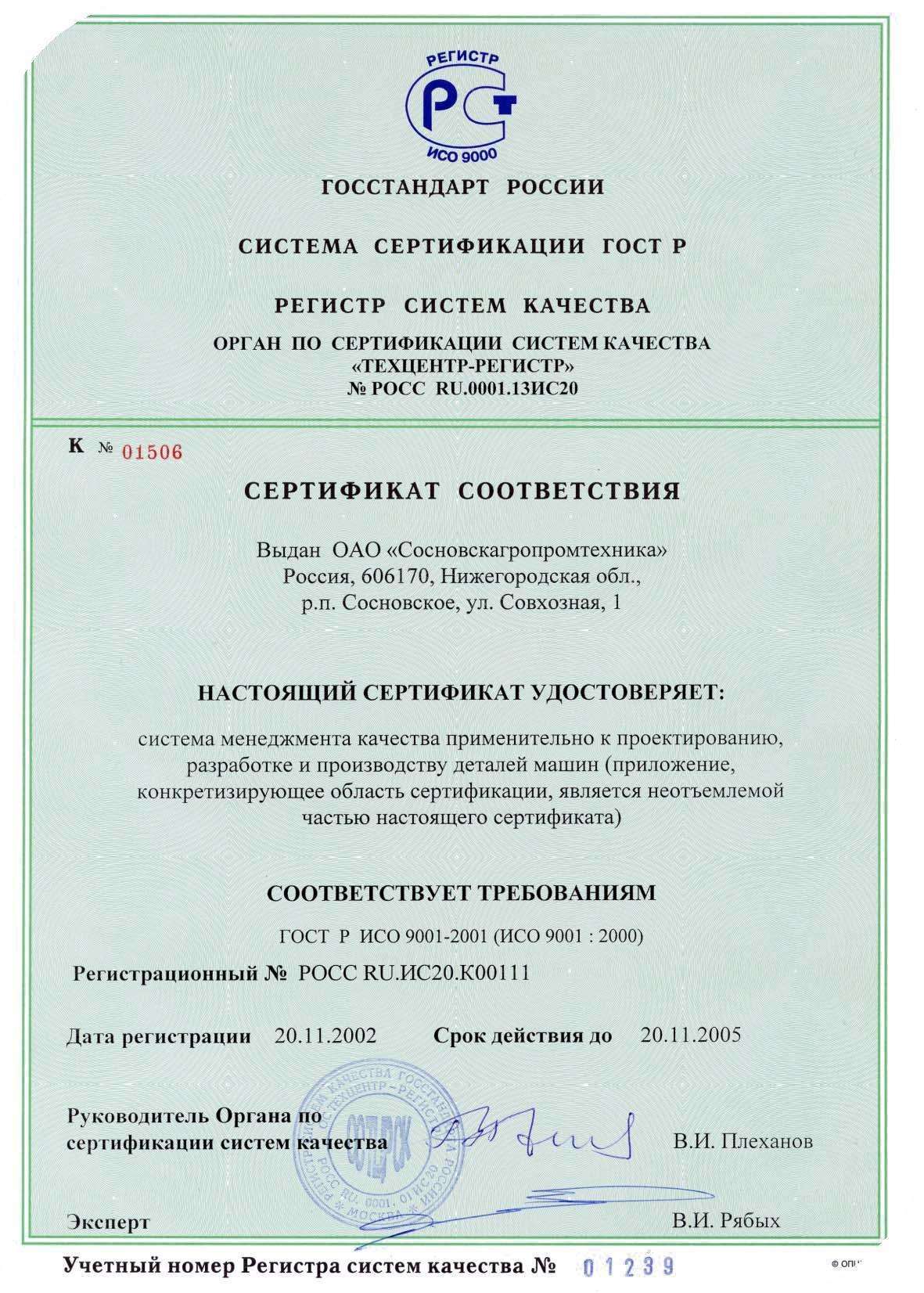

QMS certification for compliance with the requirements of GOST R ISO 9001 ver. 2001

Commissioning and launch of the Injection Moulding Machine Workshop.

Implementation of the project to purchase a new advanced extrusion line and the simultaneous completion of the new extrusion shop building construction.

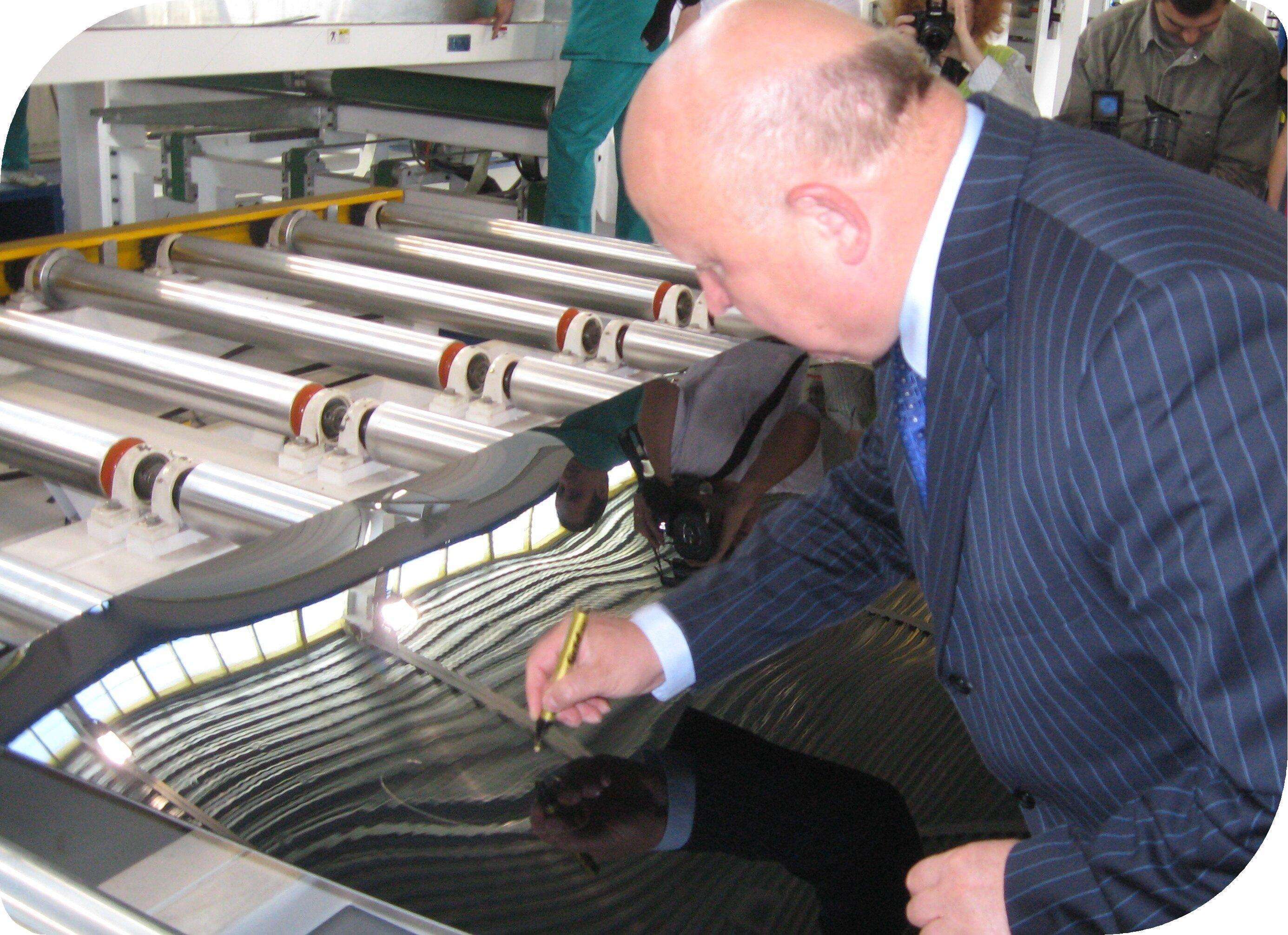

Testing the new imported extrusion line

The Company purchased auxiliary equipment and releases high quality and in-demand sheets for the motor-vehicle industry.

Commissioning of the first Italian 5-axis machining centre CMS ARES 36/18.

Commissioning of the second Italian 5-axis machining centre CMS ANTARES 26/15.

Certification of the Quality Management System

for compliance with the requirements of the international standard ISO/TS 16949-2002 by TUV CERT Certification Authority. Start of an innovative project to purchase a new generation extrusion line.

Commissioning of the extrusion line to manufacture ABS+TPU sheets

In Russia, the economic crisis was at its worst. We did not stop implementing innovative projects and commissioned the extrusion line to manufacture ABS+TPU sheets (similar to SENOSAN sheets) up to 2200 mm wide. Additionally, the Company commissioned the third machining centre CMS ATHENA

Our Company successfully made it through the economic crisis

The extrusion line, launched in 2009, started operating at full power. The Company introduced the process of manufacturing polyurethane compound parts and embraced sheet production technology with a top decorative PVC film layer. The Company started to implement new innovative projects.

New equipment was purchased and commissioned

The Company purchased and commissioned a new HAITIAN MARS 8000/6800B injection moulding machine, a new FANUC robot-based machining centre, the GEISS Du 2000 T6 vacuum forming machine with a 2000 × 3000 working table, a new TF MILLENIUM 600 PLUS vacuum forming machine with a 2000×3000 working table. The Company developed a scheme and started to construct a handling site for extrusion shop No. 2. For the foundry's requirements, the Company purchased and commissioned a new vibration machine VU-100.

Our Company continues to grow

The construction of the handling site for extrusion shop No. 2 was completed. The Company selected the casting machine and made the first payments for it. The Company developed a scheme and started to construct extrusion shop No. 3, selected extrusion line No. 4 and made the first payments for it. The Company purchased and commissioned a new CMC ATXENA 3015 machining centre and a new thread-cutting machine with a multi-spindle head.

Commissioning of new extrusion shop No. 3. The Company purchased a new extrusion line for the manufacture of polypropylene and polyethylene sheets.

Implementation of a programme to purchase a new Injection Moulding Machine.

Scaling-up, production and integration of new technologies the manufacture of our fibreglass product range.

Construction of new buildings for the manufacture of polymeric composites.

Record sales and production results.

Construction of new manufacturing sites. Expansion of the current product range.

25 years of operation! Anniversary of the Joint-Stock Company.

The Company purchased new Italian equipment for the extrusion production of tie plates. Development of new fibreglass production technologies.

Start of new foundry projects. New investments in extrusion production based on the second tie plate production line

New targets in the development of composite production technologies. Start of plastic welding production

Competition for new market shares. Work in turbulent times under the restrictions imposed due to COVID19

Development of production using injection-moulding machines. Commissioning of extrusion line No. 7